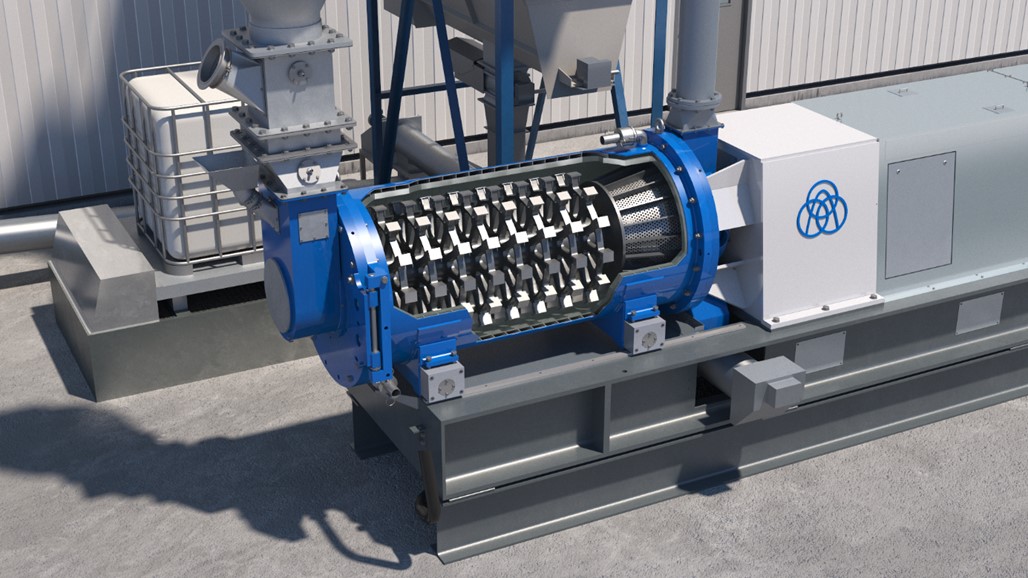

The system includes the polysius® booster mill, the ultrafine separators sepol® UF and its ancillary equipment including material handling equipment and process gas management. thyssenkrupp Polysius will also provide site services and technical support for performance optimization. Equipment deliveries are scheduled through late summer 2025 for a startup in the beginning of winter 2025.

Xenia Schulze Bernd, Head of Innolab: “Ultrafine grinding and separation is an enabler for clinker factor reduction and efficient production of special products. Expecting a market demand for big volumes of high fineness products, we have developed a polysius® ultrafine grinding plant to complement our grey2green portfolio. We are grateful for the collaboration with the innovative partner Eqiom/CRH to implement this technology in Europe."

Ultrafine grinding and separation is an enabler for clinker factor reduction and efficient production of special products.

Xenia Schulze Bernd, Head of Innolab

Layal Haddad, Project Manager adds: “Aware of the stakes of tomorrow and beyond, Eqiom/CRH places great value on sustainability. With our ultrafine production technology we are proud to play our part in decarbonation to reduce carbon footprint of cement. This is the first ultrafine grinding plant based on booster mill technology to be sold worldwide. We look forward, together with the Eqiom/CRH team, to a successful project. “

Luc Cousin, EQIOM technical director, and Pierre Bernard, EQIOM cement operation director: “We thank thyssenkrupp Polysius for the support in developing a new process and new equipment to support the development of our products. “