The polflame® VN from thyssenkrupp Polysius relies on high-end components. At the same time, thyssenkrupp Polysius stands out with excellent service, especially in maintenance, repair, and modernization.

Upgrades and retrofits are possible in a modular fashion. In the area of the coal dust connection, the coal dust channel is lined with wear-resistant material. By opening the inspection cover, the inlet zone can be inspected and the wear protection replaced if necessary. If requirements change—for example, regarding burner performance or fuels—the center, burner tip, and primary air nozzles can be easily adapted to the new conditions thanks to the modular design of the polflame® VN. Wear parts such as the outer mouthpiece can be easily replaced, and fuel lances can be retrofitted.

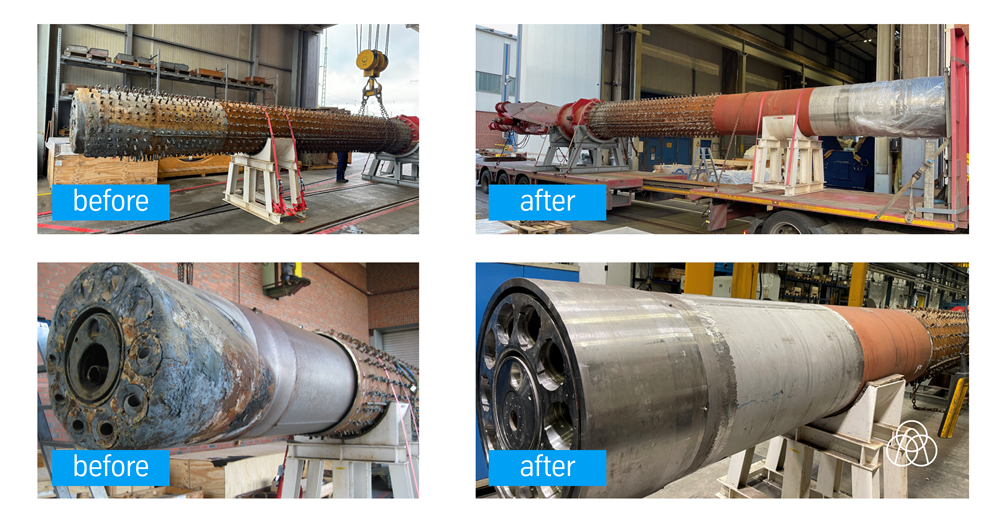

A few months ago, a customer commissioned us to repair their clinkering zone burner after a typical heat damage incident.

The repair included the disassembly of defective components, replacement of blocked bolts, and reassembly of the burner tip, nozzle adjustment, jacket pipe, mouthpiece, and burner tip disc. In addition, new nozzles with housing were installed.

Special tools enabled the precise replacement of large pipe segments, while the use of dies, cranes, and other lifting equipment ensured safe and efficient handling of the burner. Heavy loads, particularly the weight of the burner tip, were precisely aligned and expertly welded.

For the repair, the customer pre-ordered the most common and essential spare parts, allowing them to be installed without any waiting time.

In addition, our fast response times enable the short-term provision of any additional components required. After the successful repair, the burner was returned to the customer on schedule.